three piece can manufacturing process?

A three-piece can is also called a seam can. It consists of a can body, a can lid, and a can bottom. The material used is mainly tin-plated sheet steel (tinplate and chrome-plated sheet steel).

Since the advent of canning in the early 19th century, three-piece cans have been used as the main packaging container in the food canning industry. The three-piece tinplate cans produced in the early days, whether it is blanking, molding, or the sealing of the can body, as well as the bottom and sealing, are performed manually.All seams are sealed by soldering, which has a very low production efficiency. . With the development of industry and technological progress, the welding technology has also been continuously improved: the advent of automatic can welding machines has eliminated the manual operation of the welding process; the invention of the flanging sealing machine and the use of liquid sealants have made it appear in the early 20th century The sealing (bottom) technology of the “double crimping” has gradually realized mechanization, and the production speed has continued to increase. However, since the advent of the three-piece tin can for more than 100 years, tin solder cans have always dominated.Since tin solder contains a large amount of heavy metal lead, it poses a serious threat to the food hygiene in the can, so the side seam bonding method and Welding of side seams (ie resistance welding). Now resistance welding has become the most important method for manufacturing three-piece cans of food, and soldering has been basically eliminated.

In addition to the widespread use of cans in the canning industry, three-piece cans are also widely used in other industries such as chemical industry and daily necessities. Their structures are the same, but they are different according to the requirements of use, or the structure is appropriately deformed, or a certain structure is added with appropriate accessories. For example, metal cans used for tea, biscuits, candy, solid beverages, and metal cans containing cooking oil, liquid beverages, and chemical products, are basically the same as ordinary three-piece cans.

Since China established its first cannery in 1906, the production of three-piece cans has been limited to the food canning industry. More than 20 years of reform and opening up, China’s canning industry has also developed rapidly. In addition to domestic manufacturers that can provide domestic automatic canning equipment, it has also introduced more than 100 advanced automatic canning production lines from abroad. There are hundreds of iron can manufacturing enterprises in China, and the production capacity has ranked among the top in the world. It can produce a variety of metal cans to meet the needs of the development of the national economy and the improvement of people’s living standards.

The process flow and characteristics of the three-piece can manufacturing process are as follows:

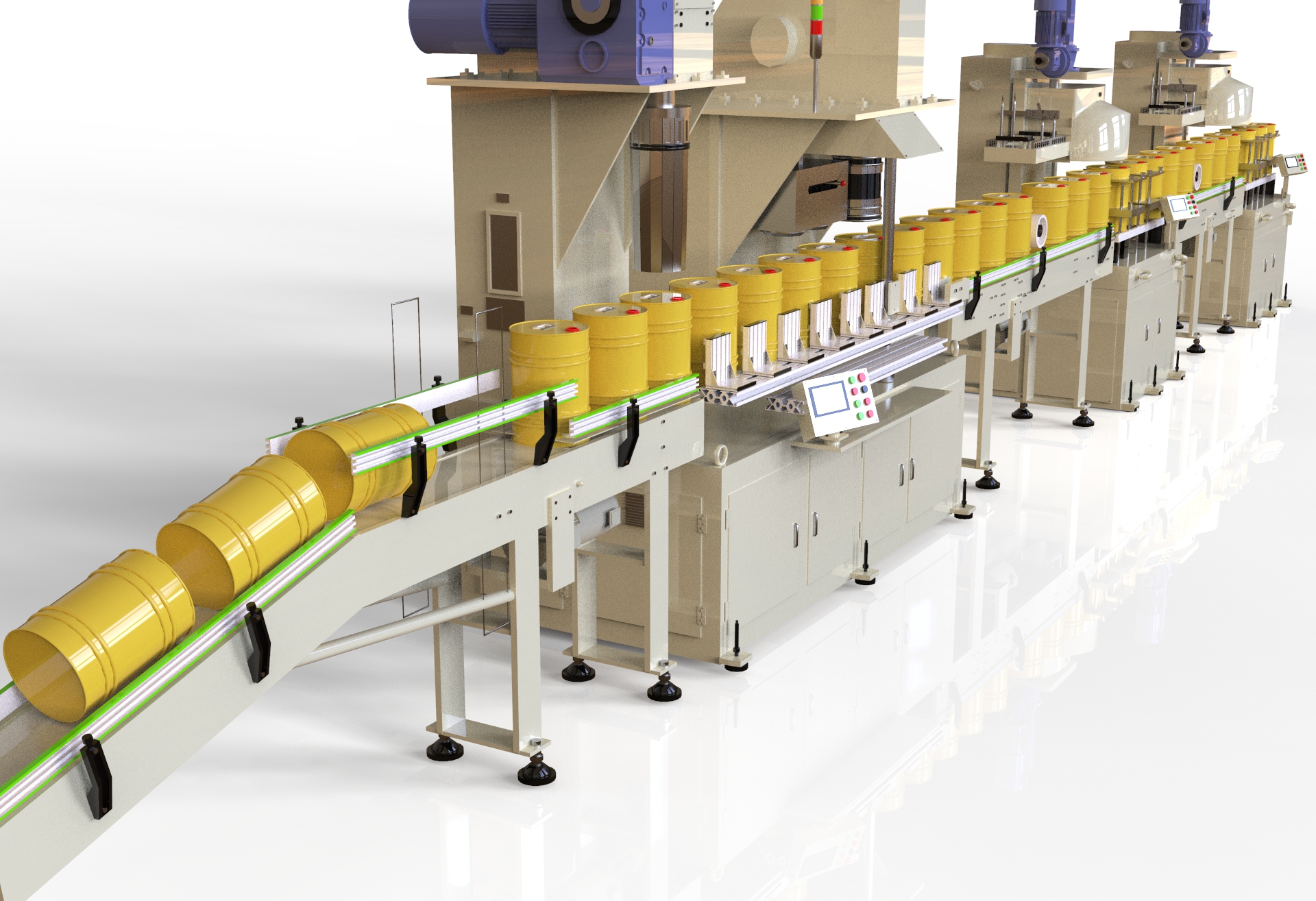

Cutting→ (scribing) → rolling → tack welding → internal and external coating→ drying → (cutting), (rolling), (neck),(Bulging), (Embossing) → Flanging →bottom seaming → Leak detection → (Full internal spray) → (Drying) → Stacking and packaging

The bracketed parts in the above steps can be configured according to the needs of the tank type.

Characteristics of resistance welding process: seam welding of the can body does not require brazing, which fundamentally eliminates the pollution of lead to the food in the solder and saves the solder; the strength of the weld is high and the seal of the weld is good; the weld overlap is small (0.25 -0.8mm), saving raw materials, narrow welding seam, especially after adding gas protection at the welding seam, the appearance is more beautiful and beautiful; the thickness of the welding seam is similar to the thickness of the tank body plate, about 1.3 to 1.5 times, which is convenient for flanging, necking, Sealing; high sealing quality, good air tightness of the can; fast production speed, up to 1000 cans / min.

Three-piece can production line equipment classification Three-piece can production line manufacturing equipment is divided into slitting equipment, expanding and welding equipment, coating equipment, dry equipment, rolling equipment, straddle cutting equipment, necking equipment, bulging, embossing equipment, flanging equipment, cap making equipment, can sealing equipment, leak detection equipment, full internal spray equipment, drying equipment, stacking equipment, packing equipment, etc.

three piece can manufacturing process?